Product Introduction

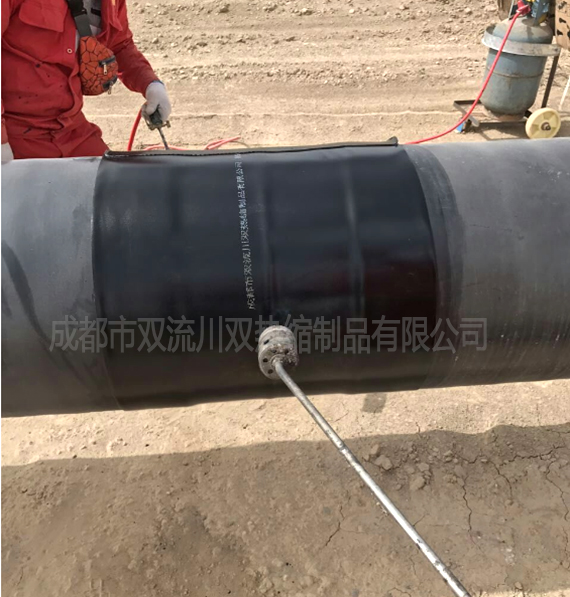

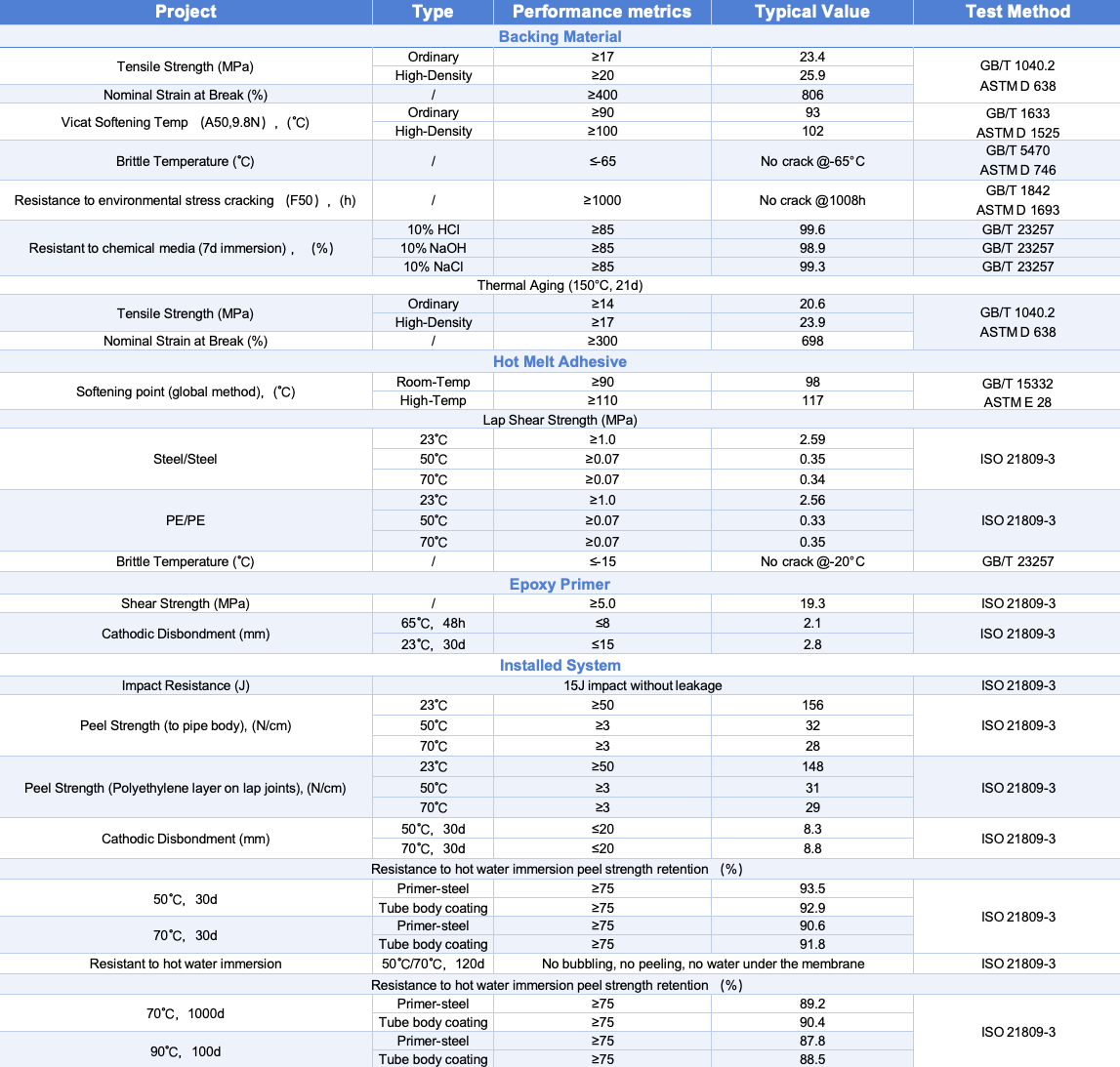

Designed for corrosion protection and insulation of buried or above-ground steel pipelines, this heat-shrinkable sleeve is primarily used for pipeline joint protection, bend wrapping, and damaged coating repairs. It can also be applied to entire pipes or irregular surfaces for complete corrosion protection. The sleeve consists of radiation-crosslinked polyolefin backing and a specialized hot-melt adhesive that bonds securely to polyethylene substrates, steel surfaces, and epoxy coatings.

The product offers excellent thermal and UV aging resistance, withstanding soil stress, hydrostatic pressure, cathodic disbondment, and chemical corrosion to provide long-term pipeline protection. Chuanshuang’s heat-shrink sleeves exceed national technical standards in tensile strength and elongation retention, ensuring reliable pipeline operation. During installation, heat application causes uniform radial shrinkage while the adhesive melts to form a continuous, tight seal with the existing pipeline coating.

Structure:

i) 3-layer version (with primer):

Base: Solvent-free two-part epoxy primer

Middle: High-performance hot-melt adhesive

Outer: Radiation-crosslinked polyethylene

ii) 2-layer version (without primer)

Features:

High mechanical strength and aging resistance

Excellent environmental stress performance

Superior adhesion properties

Outstanding cathodic disbondment resistance

Easy installation

Compliance with domestic and international standards

Applications:

Oil and gas pipelines

Subsea pipelines

Compatible with PE, FBE, and coal tar enamel coatings

Suitable for pipe diameters ≥114mm

Operating temperature: -40°C to 80°C

Maximum width: ≤1100mm

Packaging: Per pipe diameter/set

Specifications:

Backing thickness: 1.0mm to 1.8mm

Adhesive thickness: 0.6mm to 2.0mm

Types:

Standard: Maximum design temperature ≤60°C

High-Temperature: Maximum design temperature ≤80°C

相关产品

-

Heat-Shrinkable Products

Heat-Shrinkable Sleeve Tape

-

Heat-Shrinkable Products

Heat-Shrinkable Waterproof Cap

-

Heat-Shrinkable Products

Heat-Shrinkable Sleeve Tape (Round Type)

-

Heat-Shrinkable Products

Pressure-Sensitive Heat-Shrinkable Tape